Back

Back

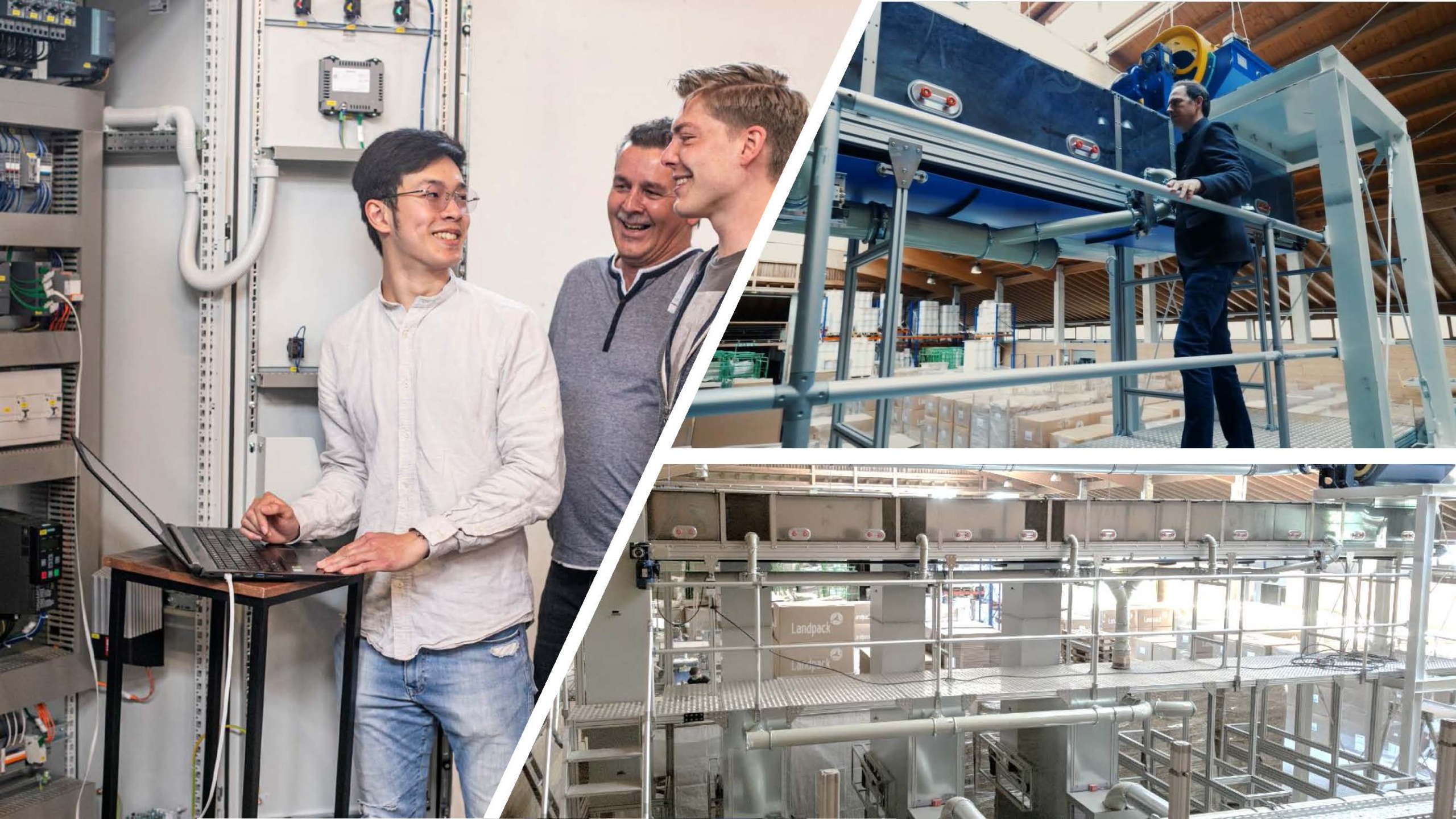

Second factory for processing straw into packaging is ready

01.05.2021 | by Christoph Humpert

In order to meet the strong demand for our sustainable insulating packaging, we have started planning for a second factory to process straw into packaging in 2019.

Our experience from three years of straw production in two-shift operation in our first factory to date has been incorporated into further technical development. Cycle times and efficiency were to be increased and artificial intelligence used for further automation and quality assurance.

In the end, our Straw Factory 2.0 became a very large project again. Construction work got underway in 2020. It has now gone into operation in mid-2021. In both factories, the fully automated processing starts with square bales of straw and ends with finished, thermally treated straw panels.

Our trained and consistent production team is responsible for picking and quality assurance. In our second factory, we also use artificial intelligence for automated quality assurance.

Both factories are powered by 100% renewable energy. Both factories are located within the Munich area. This gives us full transparency over all process stages, minimizes transport routes, and ensures truly local, ecological, and independent production.

Categories

Tags

Author

Christoph Humpert