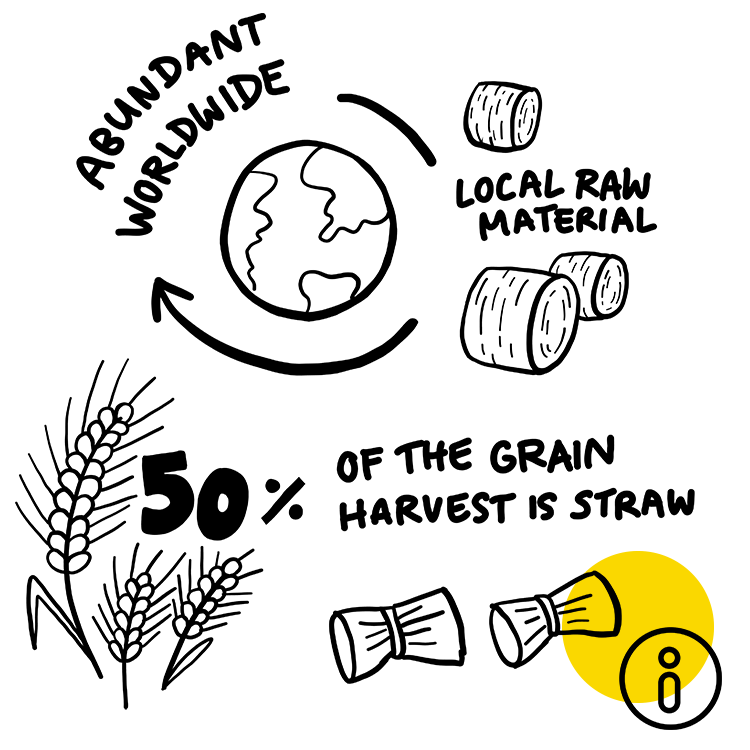

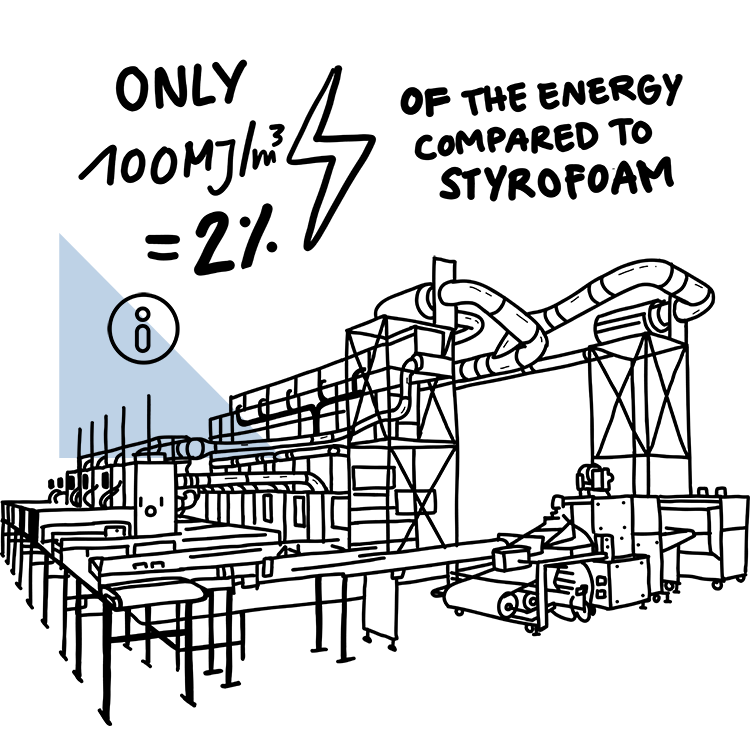

Only 1 % of the world's annual straw reserves could completely replace Expanded Polystyrene. Landpack is the first company in the world that can form straw

Biobased

Hover over the info buttons for more information about our "real" circular economy.

Impact Facts

CO2 emissions

A medium-sized Landbox (22 L, 35 mm wall thickness) causes 0.41 kg CO2eq over the entire value chain, including upstream and downstream stages, excluding biogas generation in the digestion process.

Water consumption

At 0.05 L/kg, the Landbox requires virtually no water in production. Recycled paper, on the other hand, requires 224 times as much water.

Biogas production

Based on the German energy mix, one Landbox saves 0.34 kg CO2eq through biogas extraction. The total emissions of a Landbox straw when recycled via the biowaste bin and fermentation are thus only 0.07 kg CO2eq.

Our Farmers

We use surplus straw from contract farmers in the immediate vicinity. This way, we guarantee maximum transparency, security, and honesty of supply. We tell you which field your straw comes from.

Impact